Broken sewage lines causing a back-up inside, and polluting the ground outside need to be repaired or replaced.

Traditionally, you would dig up the yard, take out the old pipe, put in a new one, put the soil back and then repair the damage to the lawn, landscaping, sidewalks, and even roadway. In some cases, an open dig is not even an option.

Today’s technology now provides trenchless alternatives to the digging and destruction of traditional pipe repair and replacement. It is becoming the preferred choice among conscious consumers.

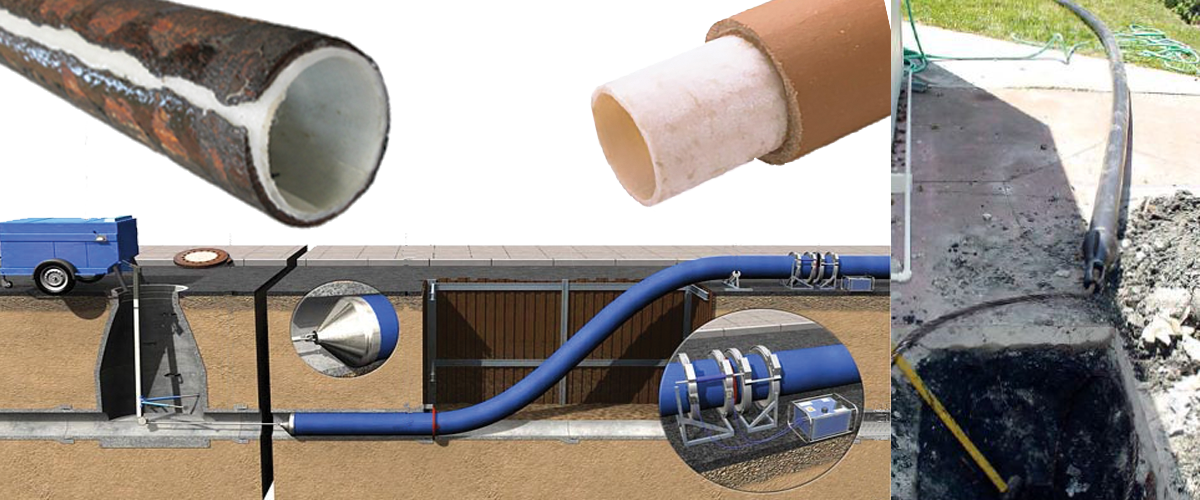

Slip Lining

Slip lining is one of the pioneering processes used in trenchless rehabilitation of pipelines. During the process, a new continuous liner of smaller diameter is placed inside the existing pipe. The area between the existing pipe and the new pipe, is typically grouted to prevent leaks and to provide structural integrity. Continuous grouting of this space provides a dependable seal.

In most slip lining applications, manholes cannot function as proper access points and it may be necessary to dig an insertion pit for each pipeline segment. Though not a completely trenchless technique, the excavation required is considerably less than that for traditional methods.

Pipe Bursting

This process starts by digging two holes, one where the sewer exits the building and the other at either the property line or in the street where it connects to the mainline. A steel cable is then threaded through the old sewer pipe and a hardened steel bursting head is attached to one end of the cable. The new polyethylene pipe is then attached to the back of the bursting head. At the other end the hydraulic system is set up which pulls the cable. Once the system has been set up and turned on the operator uses a remote control to “pull” the cable with the head and pipe attached down into the hole at the side of the house. It then pulls the new HDPE or High Density Polyethylene Pipe through the old pipe breaking it and pushing the pieces out into the surrounding soil. The new pipe gets pulled all the way to the exit hole where the connections are made, it is inspected and then the holes filled in. HDPE pipe has an estimated life of well over one hundred years.

Pipe Re-rounding

Pipe Re-rounders are used to reshape PVC sewer pipe deflected up to 15% and restore it to within 1% of the original shape.

- A special re-rounding tool is mechanically drawn through the pipe, expanding deformed sections back into the correct shape.

- Immediately afterward, the pipe is given a new, rigid lining to provide a permanent repair.

Pipe Lining / CIPP

Cured in place materials mold to the host pipe. This seamless pipe prevents infiltration and exfiltration, restores structural integrity, eliminates joints that can weaken and allow root intrusion. Cured in place pipe actually increases flow capacity because the new lined pipe is much smoother than an older clay, concrete, or deteriorated pipe. Above ground there are no mounds of excavated dirt, no plants uprooted, no traffic tie-ups and no disruptions.

Cured In Place Pipe (CIPP)

- Lateral lining

- Lateral spot repair

- Main line point repairs

- Change diameter of pipe

- Pipes of all kinds

- Pipe lengths up to 200′

- Bends through 90 degrees

- No Digging

- Seal Open Joints

- Stop Infiltration / Ex-Filtration

- Exceeds ASTM F1216 Specifications

- Eliminate Root Intrusion

- Bridge Missing Pipe Sections

- Increase Flow Efficiency

Subterrain Technologies can restore an entire lateral line or just a segment of an otherwise good pipe.The new sewer pipe repair is actually stronger than the existing host pipe and can act as a stand-alone pipe if the existing host pipe continues to fail.

Subterrain delivers results for repairing broken, cracked and leaking pipes, without the disruption of digging up the yard. Our system can be used for traditional in-ground laterals and in vertical applications on rooftops, in basements, swimming pools, skyscrapers, and more.